Can You TIG Weld Without Gas? A Comprehensive Guide 2023

Introduction

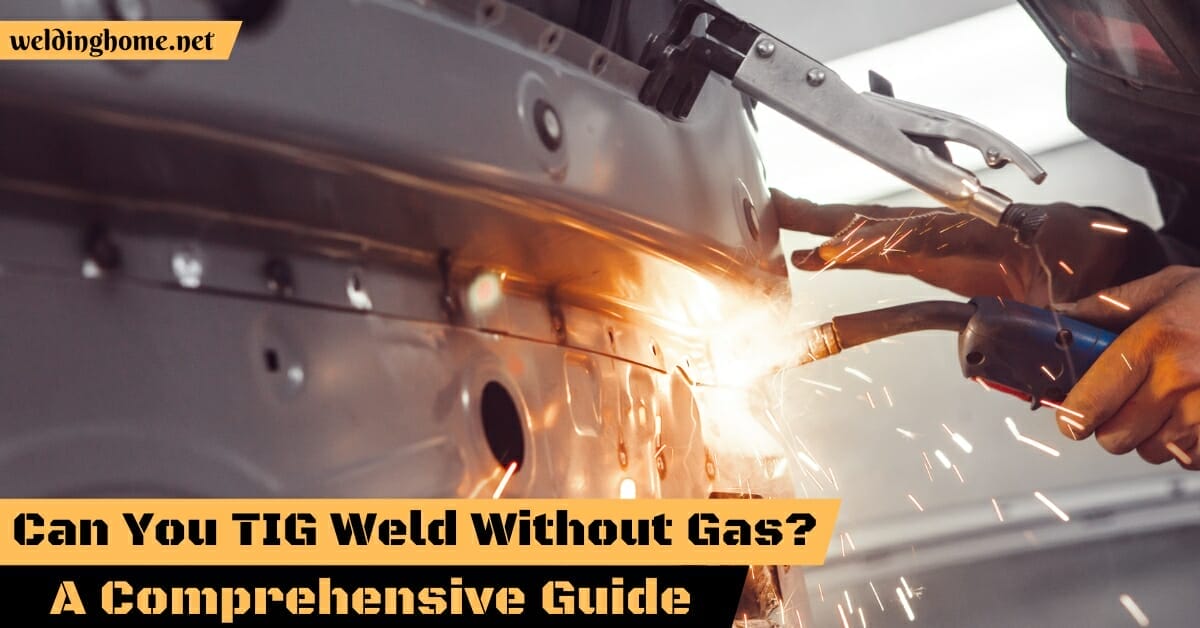

Can You TIG Weld Without Gas? A Comprehensive Guide 2023! The answer is yes, but it isn’t always the best or safest option. I m happy to learn interesting and unique facts. There are several methods and processes that can be used to TIG weld without gas, Gas is necessary for MIG welding, but it is not always the best or safest option. Explore this thorough manual to learn about alternate options and safer methods, giving yourself a variety of options to produce superior welding results.

but they all come with certain risks and drawbacks. The most common method of TIG welding without gas is called Cold Wire Welding (CWW). This process uses a filler material that is much thinner than the TIG rod, and this allows it to heat up without a gas shield. However, CWW comes with several risks due to the lack of shielding gas. These include increased chances of arc blow-outs, spatter buildup, and a higher risk of burn-through.

Additionally, the welds produced through CWW tend to be weaker than those made with a gas shield. Plasma Arc Welding (PAW) is an additional gas-free TIG welding method. This process involves using an arc from a plasma torch, which produces its own shielding gas.

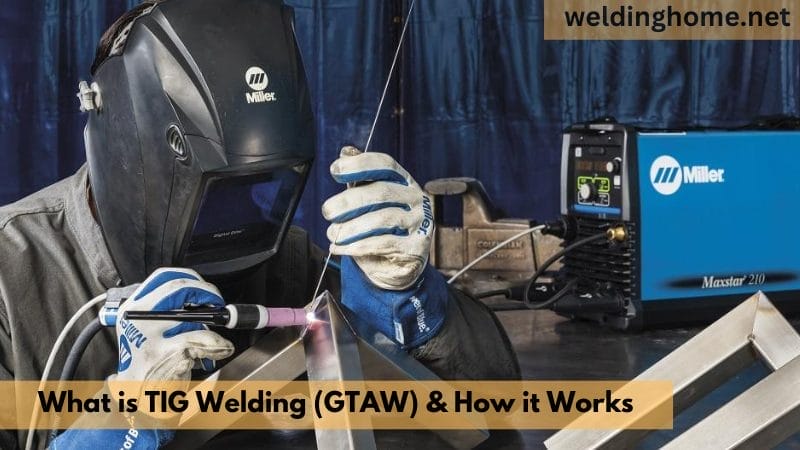

1. What is TIG Welding?

Discover the strength of TIG welding, also referred to as gas tungsten arc welding (GTAW), a commonly used method recognized for producing flawless welds of extraordinary quality. This procedure opens up a world of welding precision and expertise by using a tungsten electrode to create an arc between the electrode and the workpiece. This causes the metal to melt and form a weld. TIG welding is renowned for its precision and versatility, and it’s widely used in several industries like aerospace, automotive, and manufacturing.

TIG welding is a type of arc welding that heats the metal using a tungsten electrode that isn’t consumed. The electrode is protected by argon or another inert gas, which creates a shielding gas that prevents oxidation and contamination. TIG welding results in a precise and clean weld that requires minimal cleanup after welding.

2. How Does TIG Welding with Gas Work?

When TIG welding with gas, the tungsten electrode is held in a torch that’s connected to a power supply. The welder uses a foot pedal to control the amperage of the weld and a filler rod to add material to the weld pool. As the welder strikes an arc with the tungsten electrode, the heat melts the metal and the filler rod is added to create the weld.

The use of shielding gas is to safeguard the welded area from external elements such as oxygen and nitrogen.

3. Which type of electrodes are typically used in TIG welding?

In TIG welding, tungsten electrodes are most frequently employed. It’s made from a non-consumable material, which means it doesn’t melt when exposed to high temperatures. The type of tungsten used in TIG welding depends on the application and can range from pure tungsten to lanthanide or thoriated tungsten.

4. TIG Welding Without Gas – The Pros and Cons

It is possible to do TIG welding without gas, but there are certain advantages and disadvantages to take into account. The main advantage is that it removes the requirement of having a gas cylinder and regulator, which can be costly to buy and refill. Additionally, welding without gas can be faster than TIG welding with gas since there is no need to set up the gas shielding.

However, The use of gasless welding has some disadvantages as well. The biggest disadvantage is that the welds produced without gas can be porous and weak. Welding without a shielding gas can be difficult as it requires the welder to maintain a consistent arc length and heat input, while also preventing oxidation and contamination of the weld pool exposed to air.

5. What Equipment Do You Need for TIG Welding Without Gas?

To begin TIG welding without gas, you need to have certain equipment. You’ll require a TIG welder that can do welding without gas, a tungsten electrode, a filler rod, and a power source. Additionally, you’ll need a foot pedal to control the amperage of the weld and some protective gear like leather welding gloves and safety glasses.

To ensure proper protection from heat and sparks, it is essential for you to have a welding helmet, gloves, and jacket of high quality.

6. Do MIG and TIG welding use the same gases?

It is important to note that MIG and TIG welding use different gases. These welding procedures call for particular gases designed for their unique operations.MIG welding uses a mixture of argon and carbon dioxide or oxygen as its shielding gas, while TIG welding typically only uses an inert gas like argon or helium as its shielding gas. Additionally, MIG welding doesn’t require any filler material to complete the weld, while TIG welding uses a filler material. Therefore, MIG and TIG welding require different gases in order to complete the weld correctly and efficiently.

7. Is TIG Welding Gas Consumption Greater Than MIG Welding?

Yes, TIG welding gas consumption is generally higher than MIG welding. This is because TIG welding requires more shielding gas than MIG welding due to its need for filler material. Additionally, the type of inert gas used in TIG welding tends to be more expensive than the mixture of gases used in MIG welding. Therefore, TIG generally requires more gas and higher costs than MIG welding.

Can You TIG Weld Without Gas?

Yes, it is possible to do TIG welding without gas. However, this type of welding is not as reliable or durable as TIG welding with gas due to the lack of shielding. Additionally, the welds produced without gas can be porous and weak. Therefore, it is important to consider the pros and cons of TIG welding with and without gas in order to determine which type of welding will be best for your application.

The bottom line is that TIG welding without gas can be done, but it’s not recommended unless you are an experienced welder and have the right equipment. It is important to remember that, regardless of which type of welding you choose, safety precautions should always be taken.

Taking the time to learn more about TIG welding and understanding the differences between TIG welding with and without gas is essential for a successful weld. With practice, you’ll be able to find the right type of welding for your project and get the job done right!

Is it worth welding with TIG without using gas?

It depends on the project. In some cases, TIG welding without gas is beneficial as it eliminates the need for a gas cylinder and regulator. It can also be faster than TIG welding with gas since there is no need to set up the gas shielding. However, it should only be done by experienced welders since it requires a lot of skill and precision to produce a quality, strong weld without gas shielding. Therefore, it is important to consider the pros and cons before deciding if TIG welding without gas is right for your project. In general, though, TIG welding with gas will provide a stronger weld that is more reliable and durable.

What Other Methods Can Be Used Instead of TIG Welding with Gas?

TIG welding is the most reliable and durable method of welding, but there are other methods that can be used instead. One option is MIG welding which uses a wire feeder to melt flux-core or solid wire into a weld joint. A different choice is Flux-Cored Arc Welding (FCAW), which is comparable to MIG welding but utilizes a flux-cored wire rather than a solid wire. Additionally, oxy-acetylene welding and resistance spot welding are also popular methods that can be used in place of TIG welding.

It’s important to consider the type of weld you need and choose the method that best suits your project. With so many different types of welding out there, it’s important to understand the pros and cons of each method in order to find the best solution for your needs.

Tips for TIG Welding Without Gas

Producing high-quality welds when TIG welding

without gas can be challenging, but the correct technique and equipment can help achieve that.

To ensure a successful weld, you should use the correct electrode size and make sure to keep the arc length constant. Additionally, it is important to keep the speed of the filler rod consistent with that of the heat input so that both materials match up properly.

Conclusion

TIG welding can be done without using gas but it is not as simple as TIG welding with gas.. The welds produced without gas can be weak and prone to contamination, so it is important to have the right equipment and use the right technique. Additionally, protection from heat and sparks should always be taken into consideration when making welds without shielding gas

FAQ’S

Can I weld without gas?

While welding, the flux gives off a gas which helps shield the weld puddle from atmospheric gases, much like the way a gas that is applied while MIG welding with a gas. Keep in mind there is no such thing as “gasless welding”. Flux produces its own gas at the point of the actual weld puddle.

What is welding without gas called?

Gasless MIG

As the flux inside the wire melts, it releases its own vapors (also known as gases) to protect the pool, which bubbles to the surface to form slag over the weld. That’s why gasless welding is also known as ‘self-shielded’ welding because there’s no gas cylinder needed.

What is MIG vs TIG vs gas welding?

TIG welds typically use pure argon gas to protect the weld as the tungsten electrode is more sensitive to reactive gases like oxygen or CO2. MIG welds are typically performed with a blend of argon and CO2 (typically 75/25%), as the small addition of carbon dioxide stabilizes the arc and aids penetration.