What is TIG Welding (GTAW) & How it Works

Introduction

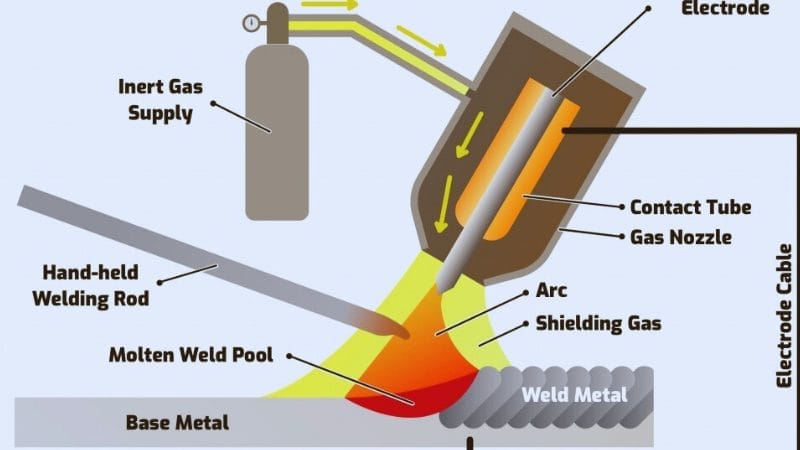

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a precise and adaptable method used in many sectors. TIG welding fuses metals precisely using a non-consumable tungsten electrode to produce an arc. This procedure What is TIG Welding (GTAW) & How it Works and uses argon to screen the welding region for air contaminants, delivering a clean, high-quality weld.

TIG welding is essential for aircraft components and delicate artwork because it can weld ferrous and non-ferrous metals and unusual alloys. Its complexity and accuracy make it ideal for crucial welds, but controlling the electrode and filler material requires experience. This TIG welding tutorial teaches us its functioning and the principles that make it a welding staple.

What is TIG Welding (GTAW) & How it Works

TIG welding is complex because it offers fine-tuned control over welding settings. The foot pedal control allows the welder to modify heat input in real-time, providing unmatched versatility. Thanks to this dynamic management, the welder can quickly react to changing circumstances while working with materials of varied thicknesses.

Filler material, a metal rod that strengthens the weld connection, is also crucial in TIG welding. Welders carefully add filler material to the molten pool to produce the weld bead. Weld strength and integrity depend on the exact filler material deposition.

TIG welding can weld different metals, which other technologies struggle with. This makes TIG welding worthwhile in businesses that combine materials, such as component and structural production.

Unlike other welding methods, TIG welding does not splatter. The regulated process reduces post-weld cleaning, saving time and money. This makes TIG welding ideal for applications that need a clean, attractive weld surface.

TIG welding’s subtle approach to metal joining, flexibility to various materials, and acceptable control mechanisms make it a welding staple. Studying TIG welding, we discover a world where artistry, technology, and metallurgy combine to create high-quality, reliable welds.

How Is TIG Different From MIG Welding?

Certainly! Here’s a comparison of TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding in a table format:

| Aspect | TIG Welding | MIG Welding |

|---|---|---|

| Electrode Type | Non-consumable tungsten electrode | Consumable wire electrode |

| Filler Material | Manually added by the welder | Automatically fed through the welding gun |

| Control | High precision and manual control | Less manual control, more automation |

| Applications | Ideal for thin materials, critical welds | Suitable for thicker materials, high production environments |

| Speed | Slower due to manual feeding of filler | Faster due to automatic wire feed |

| Shielding Gas | Typically inert gases like argon | Mix of inert and active gases (e.g., argon and CO2) |

| Weld Appearance | High-quality, aesthetically pleasing welds | Faster, may require more post-weld cleanup |

| Versatility | Suited for various metals and alloys | Versatile, but may have limitations with certain materials |

| Common Industries | Aerospace, automotive, art | Manufacturing, construction, automotive fabrication |

This table summarizes some key differences between TIG and MIG welding, highlighting their distinct characteristics and areas of specialization.

What Do I Need To TIG Weld?

You’ll need specific gear to TIG weld, though it can be a bit pricey compared to other welding types like MIG or stick. Here’s what you’ll require:

- TIG Welder: This is the main machine and is usually the most expensive part. Make sure it supports AC TIG output if you plan to weld aluminum.

- Tungsten Electrode: There are different types, like lanthanum or cerium, but avoid thoriated tungsten as it’s radioactive. Lanthanum is a safer alternative.

- Filler Rods: These vary based on the material you’re welding. For mild steel, use ER70S-6; for stainless steel, use ER308; and for aluminum, go for ER4043.

- Shielding Gas Tank: Get your tank instead of renting; it’s cheaper. Usually, argon works for most jobs.

- Welding Helmet: Make sure it’s suitable for low TIG amperage, especially if you’re working with thin materials that need a soft amp start.

- Gloves: Use lightweight, flexible goatskin gloves designed for TIG welding, not heavy-duty ones for MIG or stick welding.

- Foot Pedal: This helps control the amperage in real-time, but not all welding machines support it.

Remember, TIG welding takes practice, so be patient. It’s okay if your welds don’t look perfect at first. Even the pros are always learning. With time, anyone can create beautiful welds, starting with simple ones and progressing to more complex joints and materials.

Advantages & Disadvantages Of TIG Welding

Certainly! Here’s a simple table outlining the advantages and disadvantages of TIG welding:

| Advantages of TIG Welding | Disadvantages of TIG Welding |

|---|---|

| Advantages: | Disadvantages: |

| 1. Precise and High Quality | 1. Slower than other methods |

| 2. Suitable for Thin Materials | 2. Requires more skill and practice |

| 3. Versatile with Various Metals | 3. Equipment is more expensive |

| 4. Clean and Aesthetic Welds | 4. Not as fast as MIG welding |

| 5. Little to No Splatter | 5. Limited in vertical welding |

This table simplifies the key pros and cons of TIG welding, making it easy to understand.

Careers In TIG Welding

A career in TIG welding offers a range of opportunities for skilled professionals in various industries. TIG welding’s precision and versatility make it a sought-after skill and individuals with expertise in this method can explore several rewarding career paths. Here are some notable careers in TIG welding:

- Aerospace Welder: TIG welders are crucial in the aerospace industry for assembling aircraft components. The demand for precision and strength in aerospace materials aligns well with the characteristics of TIG welding.

- Pipeline Welder: TIG welders play a role in pipeline construction, particularly for welding pipes made of stainless steel or alloys. This ensures the integrity of the pipelines that transport liquids or gases.

- Automotive Welder: TIG welding is employed in the automotive sector for crafting exhaust systems, chassis components, and other critical parts. The method’s ability to weld various metals makes it valuable in this industry.

- Artistic Metalworker: TIG welding’s finesse makes it a favorite among artists and craftsmen working with metal sculptures, artwork, and customized designs. The precision allows for intricate detailing and aesthetically pleasing results.

- Pressure Vessel Welder: TIG welding is used to fabricate pressure vessels, where precision welding is essential to ensure the structural integrity and safety of the vessels.

- Pipefitter: TIG welding is frequently utilized in pipefitting jobs, where accurate and reliable welds are necessary for connecting pipes in various industrial settings.

- Nuclear Welding Technician: TIG welding is employed for welding components in reactors and other nuclear facilities in the nuclear industry. The method’s precision and ability to work with different metals are crucial in this field.

- Shipbuilding Welder: TIG welding is employed in the construction of ships, ensuring the strength and durability of the welded joints in various marine applications.

- Pharmaceutical Equipment Welder: TIG welding fabricates stainless steel components for pharmaceutical equipment, meeting stringent hygiene and quality standards.

- Specialized Welding Inspector: With experience, TIG welders may pursue a career as welding inspectors, ensuring that welding processes meet industry standards and specifications.

These diverse career options highlight the significance of TIG welding across industries, allowing professionals to specialize in areas that align with their interests and skills. Continuous learning and hands-on experience are key to advancing a TIG welding career.

Conclusion

In conclusion, TIG welding offers several aerospace, automobile, arts, and nuclear technology job paths. The accuracy and adaptability of TIG welding make it essential for experts who like making structural components and elaborate metal artworks. Because many applications need accurate and high-quality welds, TIG welder demand is rising. As we explore TIG welding occupations, we see that mastering is a skill that grows with each project.

TIG welders shape the world by building infrastructure and adding beauty to metal creations. The TIG welding profession is a dynamic exploration of talent and invention in metal joining that requires constant study and devotion.

FAQS

Does TIG welding have what benefits over other methods?

Gas Tungsten Arc Welding (GTAW) is known for its accuracy and adaptability. The benefits include smooth, high-quality welds for thin materials, adaptability in welding different metals, and minimum spatter. Knowing these advantages helps people pick the proper welding procedure.

How can I choose TIG welding equipment for my project?

TIG welding equipment selection depends on the metals to be welded, their thickness, and the welding machine’s characteristics. Choosing the right tungsten electrode, filler material, and shielding gases improves welding performance.

What careers await TIG welders?

TIG welding offers several job options. TIG welders may work in aerospace, automotive, art, and pipeline construction. By understanding the breadth of jobs, aspiring welders may match their abilities to sectors that meet their interests and aspirations.