Adjusting the AC Frequency for TIG Welding Aluminium 101

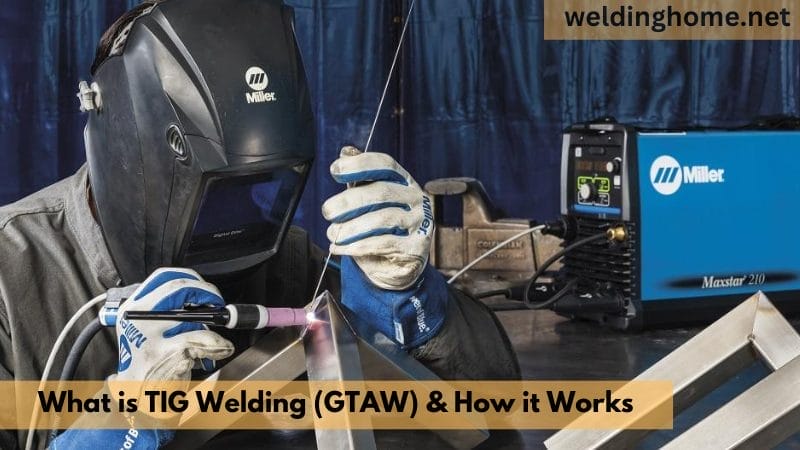

Tungsten Inert Gas (TIG) welding is a widely used process known for its precision and versatility. Welding is the preferred choice for welding aluminium because it can produce clean and high-quality welds. Welding aluminium can pose challenges due to its high thermal conductivity and low melting point.

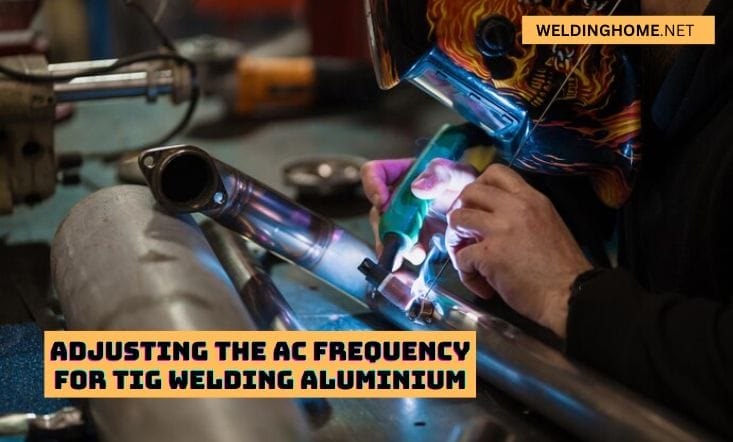

Adjusting the AC frequency TIG Welding Aluminium is a standard tactic welders use to overcome these obstacles and produce high-quality TIG-welded aluminum. In this article, I will deeply define the importance of high AC frequency adjustment, its benefits, and the best methods for achieving exceptional results.

TIG Welding 101:Understanding the TIG Welding Aluminium

TIG welding requires an understanding of alternating current frequency.

The electrical current that is used in TIG welding Aluminium can be set to alternate between two different values: positive and negative. Alternating current, abbreviated as AC, refers to the current movement in a back-and-forth pattern. The number of times the current reverses direction in one second is called the alternating current frequency, measured in hertz (Hz).

Adjusting the AC frequency is essential when TIG Welding Aluminium because it determines the shape of the weld bead and the depth to which it penetrates. The weld pool can be controlled more precisely when the AC frequency is higher because the resulting arc is more concentrated and narrower. On the other hand, a lower AC frequency TIG Welding Aluminium causes the arc to become more expansive, which can be advantageous for the distribution of heat over larger weld areas.

How to Change the AC Frequency in the Best Ways

Aluminium oxide can significantly affect the quality of welds produced by TIG Welding Aluminium. When aluminum is exposed to air, a naturally occurring compound called aluminum oxide forms on its surface. A thick oxide layer can prevent proper fusion during welding, resulting in weaker welds.

Successful TIG welds on aluminium require the aluminium oxide layer to be removed or reduced. A stainless steel wire brush or chemical cleaners are commonly used before welding. Oxide removal makes the base metal more receptive to welding, improving fusion and stronger welds.

Welders can also prevent aluminium oxide from forming by controlling shielding gas flow. The shielding gas (typically argon) helps prevent further oxidation by producing an inert atmosphere around the weld area.

Welders can overcome the obstacles presented by aluminium oxide and produce flawless welds with superior strength and appearance by thoroughly cleaning the aluminium surface and ensuring adequate shielding gas coverage.

How to set AC frequency for TIG Welding Aluminium

Understand the Material:

Different AC frequencies may affect different types of aluminium alloys. Get to know the aluminium alloy you are working with so you can figure out the best AC frequency TIG Welding Aluminium range.

Think about the thickness of the weld. A higher AC frequency is usually better for thinner aluminum materials to avoid putting in too much heat. Using a lower AC frequency on thicker materials may be better for spreading the heat around.

Practice and try different things:

You must practice and try different things to learn how to change the AC frequency of the TIG welding aluminium. Take the time to practice on scrap aluminium pieces to learn how the AC frequency affects the weld pool and how well the welding works.

Monitor Welding Parameters:

Keep a close eye on the welding parameters, such as the AC frequency, amperage, and travel speed. Small changes, like changing the AC frequency, can help get your desired results.

Even with the right AC frequency setting TIG Welding Aluminium, using the proper welding technique is essential.

Weld Thickness:

Think about how thick the thing being welded is. Thinner materials usually need higher AC frequencies to avoid getting too much heat, while thicker materials may need lower AC frequencies to spread the heat better.

Practice and experimenting are needed to learn how to change the frequency of an AC. Take the time to practice on scrap materials to see how changing the AC frequency affects the welding arc, the weld pool, and the overall welding performance.

How to Choose the Right AC Balance:

The AC balance is the current amount of time spent in the positive and negative cycles during each AC cycle. Adjusting the AC balance correctly lets you control how much cleaning and penetration is done, directly affecting the weld’s quality.

Even with the right AC frequency setting, using the proper welding technique is essential.

Use the Right Electrode:

The right tungsten electrode is essential for TIG welding. It would help if you used pure or tungsten mixed with a small amount of thorium or cerium for aluminium.

Clean the Surface:

Before you weld, ensure the aluminium surface is clean and free of dirt and aluminium oxide. Use a wire brush of stainless steel or chemical cleaners to remove any oxide layer. This will make welding go more smoothly.

Shielding Gas Flow:

Control the shielding gas flow to create an inert atmosphere around the weld area. This will stop any more oxidation from happening while you are welding.

Safety Precautions:

Always wear the proper personal protective equipment (PPE), like welding gloves, a helmet, and clothing, to protect yourself from potential dangers during welding.

Conclusion

Adjusting AC frequency in TIG welding aluminium is a technique that can significantly benefit welders by enabling them to achieve exceptional results. Welders can achieve high-quality welds on aluminium materials of different thicknesses by effectively controlling the welding arc’s shape, penetration, and heat input.

Welders can enhance their TIG welding skills and achieve high-quality aluminium welds by practising, experimenting, and following best practices, including making AC frequency adjustments.

FAQ’S

What is the best TIG welder setting for aluminium?

The rule of thumb for aluminium GTAW is to use 1 amp for every thousandth (0.001) of material thickness. In other words, welding a base material that is 1⁄8 in. (0.125) thick would require about 125 amps.

What is the frequency setting for TIG welding?

The higher AC frequency settings can be helpful for thinner aluminium or when building up on the edge of thin aluminium. And here is another golden rule of thumb… if you have enough amperage, an AC frequency setting of 100-120hz is an excellent all-around setting for most anything.

What is the best frequency for TIG welding aluminium?

Frequencies between 80 and 120 Hz are comfortable to work with, increase arc control, and boost travel speeds. Setting the frequency from 120 to 200 Hz is ideal for most aluminium welding.